The data from the PSHEs and the WPHE, along with single- and phase-change data from other commercially available chevron-type corrugated plate heat exchangers (e.g., PFHEs), provide HTRI with a strong foundation for developing generalized heat transfer and pressure drop methods for corrugated crisscross channels and enhancing our software capabilities in the future. Both reports also discuss using X phe ® to model PSHEs and WPHEs. PHE-18-TR documents shellside flow boiling data in a PSHE provided by Vahterus Oy.

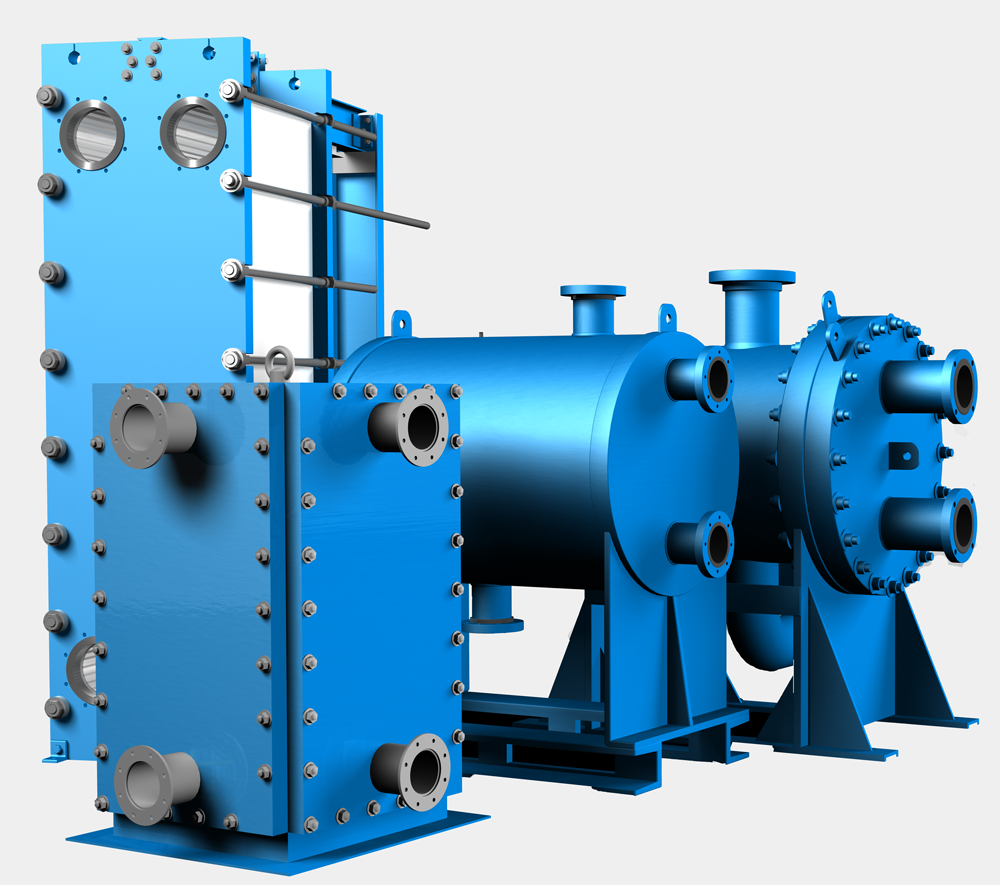

The data indicate that thermal and vapor-liquid stratifications are possible for horizontal flow in vertical channels. Frames, plates and connections can be combined to form a. This is the first time HTRI has collected boiling data and hydrocarbon condensation data in a WPHE. Plate heat exchangers are built on a module-based concept and are designed to provide maximum efficiency in transferring heat from one liquid to another, or from steam to liquid. PHE-17-TR documents liquid-phase and flow boiling data in a WPHE provided by Hisaka Works, Ltd. Except for this Instruction Manual, the following documents are also included in this shipment: Plate Heat Exchanger (PHE) drawing. In 2018, HTRI published two reports on PHE research. and Vahterus Oy) and one WPHE (provided by Hisaka Works, Ltd.). It is up to you to decide which method is. We collaborated with plate heat exchanger manufacturers and collected significant amounts of liquid-phase and phase-change heat transfer and pressure drop data on three PSHEs (provided by Tranter, Inc. Both reactive or proactive approaches to maintenance have advantages and disadvantages. In an effort to improve our plate heat exchanger technology, HTRI initiated a multi-year technical program to conduct experimental and analytical research. In the past, HTRI research and software of plate heat exchanger technology focused mostly on PFHEs.

0 kommentar(er)

0 kommentar(er)